Electroluminescence Testing of Solar Panels

Solar energy is a rapidly growing renewable energy source, and photovoltaic (PV) solar panels are the primary means of harnessing this abundant resource. However, ensuring the long-term performance and reliability of solar panels is crucial for the sustainability of solar energy systems. An important method employed to assess the quality and integrity of solar panels is electroluminescence (EL) testing.

Principle

Electroluminescence is the phenomenon where a material emits light when subjected to an electric field. In the context of solar panels, EL testing involves applying an electrical bias to the solar cells, causing them to emit light. This emitted light reveals various defects and anomalies within the solar cells, such as cracks, delamination, soldering defects, and any electrical discontinuities. By analyzing the patterns and intensity of the emitted light, technicians can identify faults and assess the quality of solar modules

Examples of Defect Types

Microcracks, cell cracks, soldering defects, PID defects, dead cell, short circuit, disconnections or shiŌing problems are among mostly detected defects by EL technique. Below there are examples of different faults which can be detected via EL images.

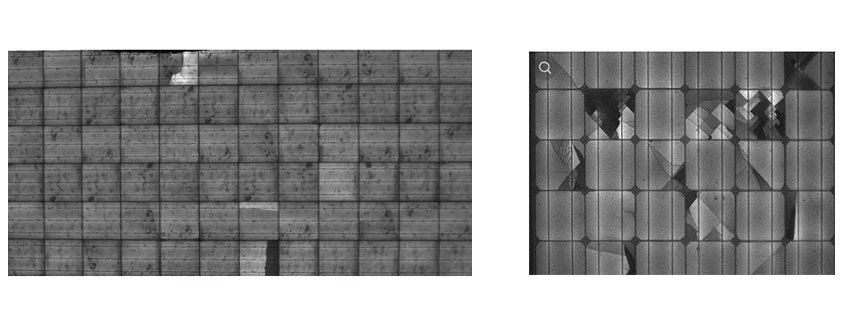

Examples of cell cracks

Example of multiple micro-cracks

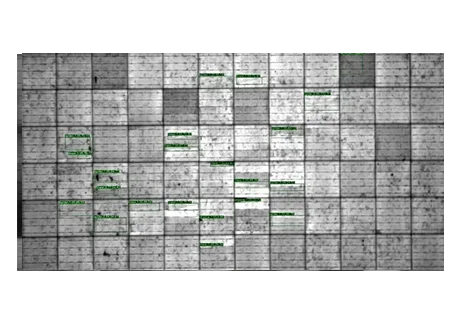

Examples of PID problem

Example of dead cell/short circuit situation

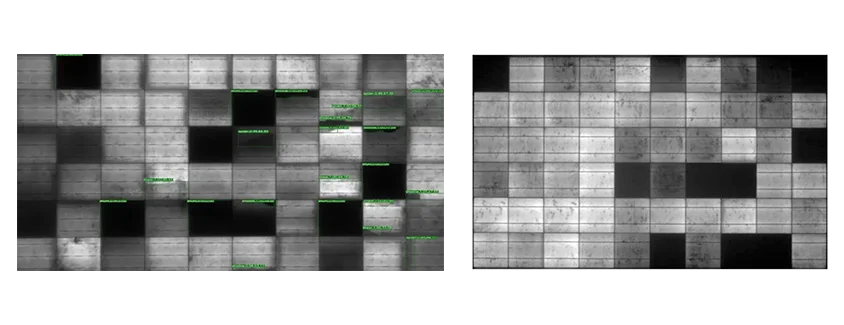

Example of cell array shithing

Example of tabbings disconnection

Quality Control

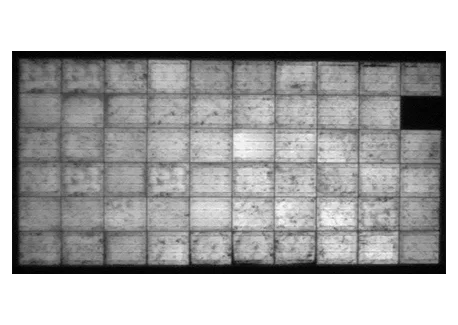

EL testing is used during the manufacturing process to detect defects in solar cells either before or aŌer they are assembled into modules. EL testing before lamination of solar panels allow manufacturers to observe defects and fix since the integrity of solar modules are not yet finalized. By identifying and rectifying these defects early on, manufacturers can improve the overall quality and reliability of solar panels. EL testing aŌer lamination of solar panels is used again to confirm performance level and classify panel with respect to test results if required.

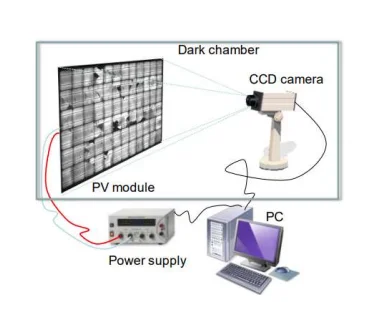

Schematics of laboratory type set-up

Quality Assurance

Solar panel manufacturers utilize EL testing as part of their quality assurance procedures to ensure that modules meet targeted performance and durability standards. EL testing provides prevention of faulty product delivery to to customers.

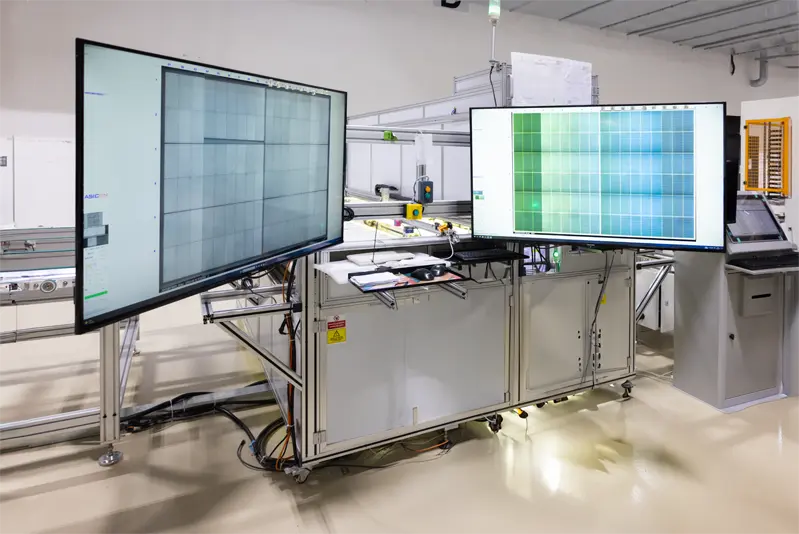

Industrial EL Tester on Solar Panel Manufacturing Line

Field Inspections

EL testing is can also be employed during field inspections of installed solar panels. By conducting periodic EL tests, operators can assess the condition of solar panels, identify potential issues, and schedule maintenance when necessary. Maximizing the lifespan and performance of solar panels can be achieved by periodical field inspections.

EL Testing on Field

Early Detection of Defects

EL testing allows for the early detection of defects and anomalies in solar panels, enabling timely corrective actions to be taken. This helps prevent performance degradation and ensures the longevity of solar energy systems.

Non-Destructive Testing

Unlike mechanical inspections, EL testing is a non-destructive method, meaning that it does not damage or change the solar panel structure under examination. This feature makes EL testing a highly valuable tool for both manufacturers and field applications on customer side.

Comprehensive Analysis

EL testing provides a comprehensive analysis of solar panel integrity by revealing all internal defects or imperfections which cannot be observed through visual inspections alone. This allows for a more complete assessment of panel quality and reliability.

Cost-Effectiveness

In order to carry out EL testing specialized equipment and expertise knowledge are required. Despite the high initial cost, benefits from EL testing in terms of improved quality and reliability can fastly outweigh the initial investment. By minimizing the risk of premature failures and warranty claims, EL testing ultimately saves money for solar panel manufacturers and solar energy system operators.

Conclusion

Electroluminescence testing is an essential tool for assessing the quality and integrity of different PV solar panels throughout their lifecycle. There are broad fields of application of EL technique along all the entire value chain of solar energy systems, from manufacturing to the final installation and performance of the modules in the plant. By leveraging the principles of electroluminescence effect, this non-destructive testing method enables early detection of defects, ensures compliance with quality standards, and maximizes the performance and longevity of solar energy systems. The importance and utilization of electroluminescence testing to ensure the reliability and sustainability of PV panels will be crucial, as the solar industry continues to grow.

RESOURCES:

- All you want to know about Electroluminescence(EL) testing of Solar Modules

- ELECTROLUMINESCENCE (EL) TEST: AN ESSENTIAL TOOL FOR DETECTING AND IDENTIFYING DIFFERENT TYPES OF DEFECTS IN PHOTOVOLTAIC MODULES PRESENTATION 22-09-2020