POTENTIAL INDUCED DEGRADATION (PID): A THREAT TO PHOTOVOLTAIC MODULE EFFICIENCY

As the world ever increasingly turns towards renewable energy sources to meet its power needs, solar energy has emerged as a key player in search for a sustainable future. Efficient operation of solar modules is essential to maximize energy output and maintain system longevity.

The photovoltaic (PV) solar industry faces a significant challenge in the form of Potential Induced Degradation (PID), which can cause a reduction in the performance over the life time of solar modules. PID is caused by an electrical potential difference between the front and back electrodes of the module. This failure can be triggered by external factors such as humidity, high temperatures, and certain chemicals. The development of new materials and designs for PV modules that are more resistant to PID, as well as improved testing methods and PID prevention strategies have to addressed to tackle with this challenge.

Introduction

In general, PID can be caused by a voltage of a few hundred millivolts or more between the front and back electrodes of the PV module. The impact of this voltage on the performance of the module depends on the severity of the PID.

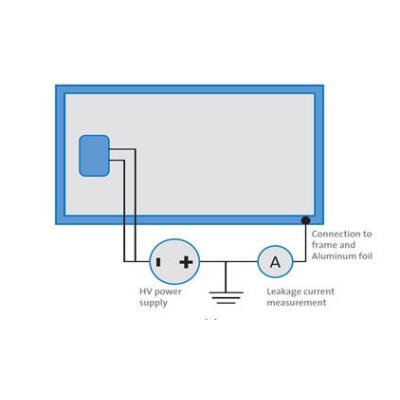

PV module is typically connected to the PID tester, with the front and back electrodes of the module connected to the tester in opposite polarity. The tester then applies a voltage and current to the module, typically at a level that is higher than the maximum voltage and current that the module is expected to encounter under normal operating conditions.

The tester will apply a voltage and current that are high enough to stress the module and simulate the conditions that could lead to PID, but not so high as to damage the module. The test typically provides data on the performance of the PV module, including any changes in power output or other parameters that may be indicative of PID.

PID Testing System

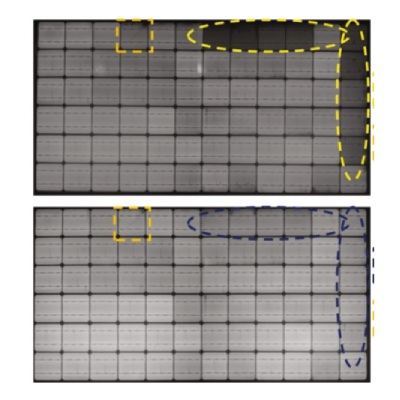

Another technique to identify PID failure is Electroluminescence (EL) imaging which is typically used to identify defects or cracks in PV modules. The information from EL imaging contributes to the durability and reliability issues. Potential difference between the front and back electrodes can cause an electrical current to flow between the electrodes, which can result in changes in the light emission patterns. By analyzing the EL images of a PV module, it is possible to identify any changes in the light emission patterns that may be indicative of PID. The reduction in light emissions is a clear indication that the PID has impacted the performance.

EL Images: The module which affected by PID on top figure has darker regions on the edges

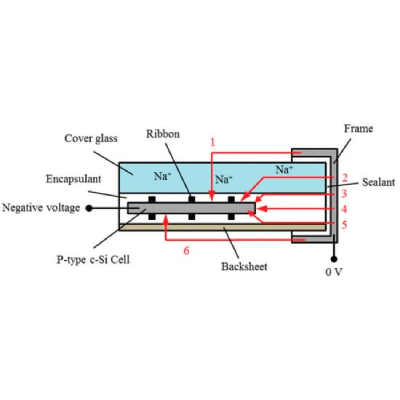

Ionic migration is one of the mechanisms associated with PID in PV modules. Sodium ions are naturally present in materials used in PV module construction, such as glass and encapsulant materials. Under normal operating conditions, these ions remain relatively stable. But, when the module is exposed to elevated voltages and temperatures, Na+ ions can drift through the module structure due to the presence of an electric field. The migration of sodium ions (Na+) through the front glass and encapsulant of conventional crystalline silicon PV modules will contribute to PID.

As Na+ ions migrate towards the negatively biased cell, they accumulate near the surface and create a localized electric field. This electric field can lead to a charge imbalance within the cell, lowering the electrical performance. The accumulation of positive charges near the surface can induce a reverse bias in the p-n junction, reducing the cell’s output voltage and ultimately its power output. The migration of sodium ions is facilitated by the presence of moisture within the module. Water molecules can provide an easy pathway for the ionic migration and increase the ionic conductivity of the encapsulant material.

Potential Paths (1,2,3,4,5,6) for Leakage Currents

Improved PID testing methods specifically to test the susceptibility of PV modules to photovoltaic PID are; Temperature and humidity cycling test, Direct current bias test, and Accelerated aging and test.

Temperature and Humidity Cycling

The module is placed in a controlled environment, typically a chamber, where temperature and humidity levels are precisely controlled. Multiple cycles of varying temperature and humidity levels are applied to the module over several days. Following the test, the PV module is assessed for any performance changes or issues indicative of PID by measuring power output, analyzing electrical characteristics, or examining EL images

Direct Current Bias Test

A DC voltage is applied to the module, at a level that is higher than the maximum voltage that the module is expected to encounter under normal operating conditions. The DC bias test is typically conducted for several days, to ensure that the module has been subjected to sufficient stress.

Accelerated Aging Test

To conduct an accelerated aging test, the PV module is typically placed in a chamber or other controlled environment, where the temperature, humidity, and UV radiation levels can be precisely controlled. The module is then subjected to a series of extreme conditions, with the temperature, humidity, and UV radiation levels being varied over a range of values.

PID Resistant Solar Modules

Manufacturers have developed PID resistant solar modules equipped with advanced technologies to mitigate degradation and maintain long-term performance. These modules employ various strategies to prevent or minimize the effects of PID, including improved cell encapsulation materials, enhanced grounding techniques, and optimized module designs.

One common approach is the use of anti-PID coatings on the surface of solar cells, which act as a barrier to prevent the migration of ions and minimize leakage currents. These coatings are formulated to withstand harsh environmental conditions and ensure long-term reliability.

Additionally, PID resistant modules often incorporate enhanced grounding systems to reduce the voltage potential between the cells and the ground, thereby minimizing the risk of PID-induced degradation. Proper system design and installation practices, such as ensuring adequate spacing between modules and employing effective electrical bonding techniques, are also crucial in preventing PID

Discussion

The reported power losses after PID testing varies greatly under the conditions that were used to test PID from study to study. Some studies use environmental chambers to simulate conditions that are similar to those experienced during actual field operations while others investigate PID in operating PV plants. The conditions that have the greater impact on the PID test can be the humidity, temperature, and duration of exposure to the external voltage.

Advancements in PID resistant technology offer effective solutions to mitigate the effects of degradation and ensure the long-term reliability of solar installations. By investing in PID resistant solar modules and implementing best practices in system design and installation, solar project developers and installers can maximize the energy yield, performance, and longevity of PV systems, ultimately contributing to the widespread adoption of clean and sustainable energy solutions.