KEY ELEMENTS FOR SUCCESSFUL LAMINATION OF SOLAR MODULES

There are several key elements that contribute to lamination, and these can vary depending on the specific application. You can explore the breakdown of some general aspects by paying attention to below subjects.

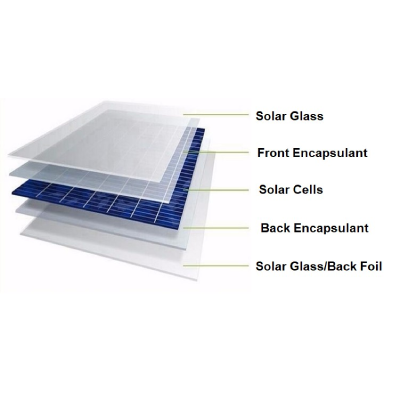

Solar PV Panel Configuration

Encapsulants (Adhesives)

This is the heart of lamination, forming a strong, durable bond between the layers. Choosing the right encapsulant type depends on the materials being laminated, the desired finish, and environmental factors.

Subsubstrate/superstrate Configuration

The materials like solar glass, polymer films, and back foil materials which are being laminated are known as substrate (or) superstrate. These materials make up the module structure intact with respect to environmental factors. Compatibility between the encapsulant (adhesive) and substrate is crucial for a good bond.

Process Parameters

Both surfaces being laminated should be clean, dry, and free of contaminants like dust (or) oil. Proper preparation ensures optimal adhesive contact.

Lamination processes involve applying heat and pressure. The appropriate settings depend on the encapsulant and substrate. Incorrect temperature (or) pressure can lead to weak bonds (or) wrinkles in the laminate.

A specific amount of time is required to achieve a full cure and maximum bond strength. Following the recommended curing time is essential.

Laminator Feed Line

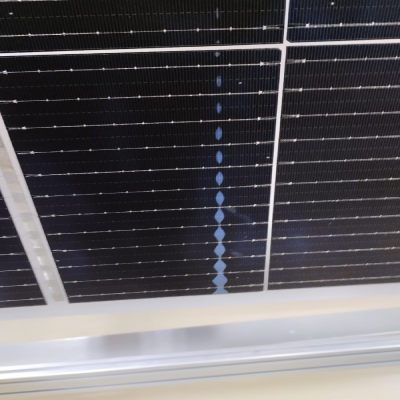

Quality Control

Visually checking for bubbles, wrinkles, (or) delamination at the edges (separation of layers) after lamination is very crucial to maintain quality.

Destructive testing also gives more insight. In some cases, specific tests have to be employed to assess the bond strength and overall quality of the lamination.

Visual Check for Bubbles

Additional Considerations

A clean work environment and dust-free materials help prevent contamination that can weaken the bond.

For solar panel applications, how the laminate will withstand UV radiation, moisture, and temperature extreme has to be considered during lamination procedure.

In some cases, the final appearance of the laminate might be the utmost important. Choosing the right materials and processes can ensure a smooth, clear finish for aesthetic look. So optical distortions have to be minimized in such cases.

Conclusive Points

Different encapsulant formulations, like EVA, POE and EPE, offer a range of quality and performance characteristics. Choosing the right one for your application ensures optimal results.

Not just the materials, but also the encapsulation method and processing conditions significantly impact the laminate quality and ultimately, the reliability of your PV modules.