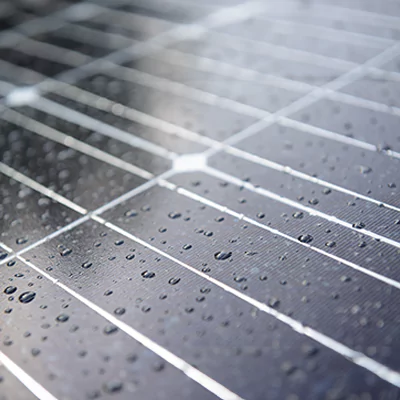

Solar modules, as integral components of solar photovoltaic (PV) systems, are subjected to various environmental conditions throughout their operational lifespan. Among these conditions, humidity and temperature fluctuations can significantly impact the performance and reliability of solar modules. To ensure the durability and longevity of solar installations in real-world operating conditions, rigorous testing protocols such as the damp heat test are essential.

The damp heat test is performed by applying 85°C temperature with a relative humidity of 85% for an uninterrupted cycle of 1,000 hours. This test is considered to be over 25 years equivalent in the harshest climate and outdoor exposure. The purpose is to determine the ability of the PV solar modules to withstand the effect of long-term penetration of humidity. This proactive approach enables manufacturers to implement design improvements and material solutions to further enhance product durability and performance. Moreover, damp heat testing is essential for complying with industry standards and certifications, such as the International Electrotechnical Commission (IEC) standards and Underwriters Laboratories (UL) certification requirements. Meeting these standards demonstrates the quality and reliability of solar modules, by building confidence in consumers and facilitating market acceptance.

Understanding Damp Heat Testing

The Damp Heat test, a subset of environmental testing, simulates the combined effects of high temperature and humidity that solar PV modules may encounter during their lifetime. Typically conducted in environmental chambers, solar modules are subjected to elevated temperatures (85°C) and high humidity levels (85% relative humidity) for an extended duration, typically around 1000 hours or more. In order to solar PV modules pass the test no significant performance degradation or structural damage should be observed after prolonged exposure to those harsh environmental conditions.

Heat and Humidity Test Chamber

Evaluation Parameters

During damp heat testing, below parameters are monitored to evaluate the performance and reliability of solar modules:

a. Power Output: The primary metric is the degradation of power output over time. Solar modules are expected to maintain their specified power output levels even under extreme environmental conditions. Any significant decline in power output indicates potential efficiency losses or material degradation within the solar panel structure.

b. Insulation Resistance: High humidity environments can endanger the insulation properties of solar modules, leading to electrical leakage or short circuits. Insulation resistance measurements are conducted to assess the ability to maintain electrical integrity in damp conditions.

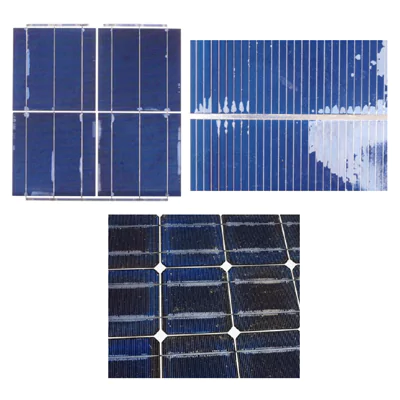

c. Visual Inspection: Visual inspection is performed before and after the test to identify any visible signs of damage, such as delamination, deterioration of glass coating, frame corrosion, backsheet cracks, attachment failures or discoloration. Detection of these visual failure provide valuable insights into the structural integrity and long-term durability of the modules.

Examples of delamination failure after heat damp test

REFERENCES

Sinovoltaics: Damp Heat Testing

Sequential and Weathering Module Testing and Comparison to Fielded Modules, NREL PV Module Reliability Workshop 2015

Hacke, P., Owen-Bellini, M., Kempe, M., Miller, D. C., Tanahashi, T., Sakurai, K., ... & Mathiak, G. (2019). Combined and sequential accelerated stress testing for derisking photovoltaic modules. In Advanced Micro-and Nanomaterials for Photovoltaics (pp. 279-313). Elsevier.