Product Explanation:

EVA (Ethylene Vinyl Acetate) FILM

For Encapsulating Solar PV Panels

![]() High Adhesion with Solar Glass

High Adhesion with Solar Glass

![]() Excellent Transparency

Excellent Transparency

![]() Outstanding Adhesion

Outstanding Adhesion

![]() UV Protection

UV Protection

![]() Snail Trail Protection

Snail Trail Protection

![]() Excellent Weatherability and Long Term Reliability

Excellent Weatherability and Long Term Reliability

Technical Specification (Dr. HWC-EU408 - ET409 Fast Cure)

| Properties | Unit | Test Method | Value | |

|---|---|---|---|---|

| EU408 | ET409 | |||

| Total Thickness ( Tolerance: ±0,05%) | mm | DR. HWC method | 0.40 ~ 0.90 | |

| Total Width | mm | DR. HWC method | Up to 1300 | |

| VA Content | % | DR. HWC method | 28 | 28 |

| Thermal Shrinkage (MD) | % | DR. HWC method(On solar glass, 3 min, 125 ºC) | ≤ 3 | ≤ 3 |

| Thermal Shrinkage (TD) | % | DR. HWC method(On solar glass, 3 min, 125 ºC) | ≤ 1 | ≤ 1 |

| Water Vapor Transmission | g/m²/24h | ASTM F1249 | ≤ 5 | ≤ 5 |

| UV Resistance (300 kWh/m²) | ΔYI | ASTM G154 | ≤ 4 | ≤ 4 |

| Humidity and Heat Resistance | ΔYI | ASTM E313 | ≤ 2 | ≤ 2 |

| Thermal Conductivity | W/(m.K) | ISO 2207-4 | 0.27 | 0.27 |

| Shore Hardness | Shore A | ASTM D 2240 | 70 ± 5 | 70 ± 5 |

| Melting Point | ºC | ASTM D3417 | 70 ± 2 | 70 ± 2 |

| Degree of cross-linking (Gel Content) | % | Soxhlet Method Lamination (14 min, 145 ºC) | ≥80 | ≥80 |

| Adhesion to Glass (With Backsheet) | N/㎝ | ASTM D 903 | ≥ 80 | ≥ 80 |

| Adhesion to Backsheet | N/㎝ | ASTM D 903 | ≥ 80 | ≥ 80 |

| Ultimate Elongation (Cured) | % | ASTM D 638 | ≥ 600 | ≥ 600 |

| Tensile Strength (Cured) | MPa | ASTM D 638 | ≥ 10 | ≥ 10 |

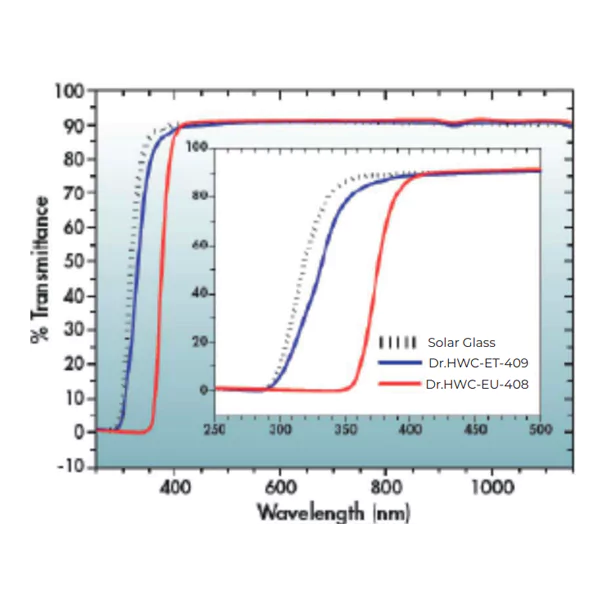

| Optical Transmittance (380nm-1100nm) | % | ASTM E424 | ≥ 91 | ≥ 91 |

| UV Cut-off Wave Length | nm | DR. HWC method | 340-360 | UV transparent |

| Dielectric strength | kV/mm | ASTM D 149 | ≥ 25 | ≥ 25 |

| Refractive Index | - | ISO 489 | 1.48 | 1.48 |

| Water Absorption (Cured) | % | ISO 62-200805 | ≤ 0.1 | ≤ 0.1 |

| Volume Resistivity (Cured) | Ω*cm | ASTM D 257 | ≥1*1015 | ≥1*1015 |

| Lamination Recipe | ||||

|---|---|---|---|---|

| Lamination Parameters | Unit | First Chamber | Second Chamber | |

| Temperature | ºC | 120 - 130 | 140 - 145 | |

| Vaccum Time | min | 4 - 6 | 3 - 4 | |

| Lamination Time | min | 8 - 12 | 8 - 12 | |

| Pressure | kPa | -70 | -50 |-25 | -70 | -50 |-25 | |

Note 1: Customers can adjust to appropriate lamination parameters according to different equipment or process

Note 2: It is recommended to use it up within 48 hours after opening of the original packing.

Note 3: These are typical laboratory values that may change depending on the cure conditions as well as the test conditions and methods.

| Light Transmittance Curve |

|---|